CLOSE

Specials

I agree We use cookies on this website to enhance your user experience. By clicking any link on this page you are giving your consent for us to set cookies. More info

Be first to read the latest tech news, Industry Leader's Insights, and CIO interviews of medium and large enterprises exclusively from Energy Tech Review

Thank you for Subscribing

Digital Transformation and Sustainability in Oil and Gas

This transformation, often called the digital oilfield, is reshaping the industry's approach to sustainability, profitability, and resilience in the face of complex global challenges.

By

Energy Tech Review | Wednesday, November 29, 2023

Stay ahead of the industry with exclusive feature stories on the top companies, expert insights and the latest news delivered straight to your inbox. Subscribe today.

The benefits of the digital oilfield extend beyond financial gains.

FREMONT, CA: The global oil and gas industry is undergoing a profound transformation driven by integrating digital technology into its core operations. This transformation, often called the digital oilfield, is reshaping the industry's approach to sustainability, profitability, and resilience in the face of complex global challenges.

Advanced sensors, Internet of Things (IoT) devices, and artificial intelligence-driven analytics continuously collect data from drilling rigs, production facilities, and pipelines. This data is then processed and analyzed in real-time, providing operators with invaluable insights into their operations. One of the most significant advantages of the digital oilfield is its ability to optimize operations and enhance profitability. By leveraging real-time data, companies can make informed decisions that improve efficiency, reduce downtime, and ultimately boost their bottom line. This newfound agility is particularly crucial in an industry where profit margins are often razor-thin and market conditions change rapidly.

Through data-driven insights, companies can monitor and reduce emissions, minimize resource wastage, and implement environmentally responsible practices. This aligns with global sustainability goals and enhances the industry's reputation and social responsibility.

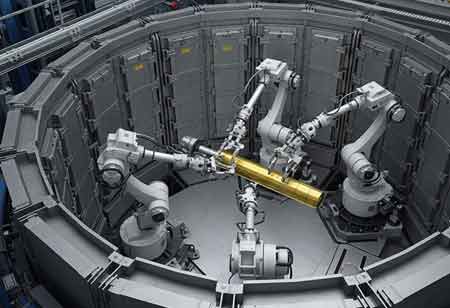

Oil and gas automation enhances productivity by entrusting repetitive, mundane tasks such as pipe handling and pressure drilling to machines. This shift liberates skilled professionals to concentrate on more intricate, analytical responsibilities. Consequently, the digital oilfield places a greater emphasis on critical-thinking work, making it more prevalent.

Another manifestation of the digital oilfield is observed through IIoT (Industrial Internet of Things) applications in the oil and gas sector. These technologies, including GPS systems, oil and gas video surveillance, and RFID detection devices, significantly enhance operational efficiency and risk management. With the advent of online oil and gas industry asset management, tasks like monitoring oil pressure, tracking deliveries, and detecting leaks can now be executed remotely and in real-time.

The allocation of profits for investment in the oil and gas industry depends on one's perspective, whether as a consumer or a stakeholder. However, these industries have reached a pivotal juncture, recognizing the advantages of digital transformation. This transformation has the potential to completely overhaul traditional Oilfield Services (OFS) business models and solutions.

Furthermore, this shift towards investment aims to facilitate the reliable and timely acquisition of vast amounts of data from every facet of field operations. Simultaneously, it seeks to generate sustainable outcomes, such as a reduced carbon footprint. These outcomes benefit consumers, employees, investors, shareholders, and the environment.

In addition to profitability and sustainability, the digital oilfield is proving to be a crucial tool for navigating the numerous global challenges that the industry faces. Geopolitical tensions, fluctuating oil prices, and unforeseen crises can all disrupt operations and threaten a company's viability. However, the digital oilfield's data-driven approach gives companies the flexibility and adaptability to weather these storms. It enables proactive risk management, scenario planning, and rapid response to changing market dynamics. Moreover, the digital oilfield supports remote monitoring and control, which has proven invaluable during times of crisis. With the ability to remotely oversee operations, companies can ensure the safety of their workforce while maintaining operational continuity, even in the face of lockdowns and travel restrictions.

See Also : Top Oil and Gas Solutions Companies

Copyright © 2025 Energy Tech Review. All rights reserved