CLOSE

Specials

I agree We use cookies on this website to enhance your user experience. By clicking any link on this page you are giving your consent for us to set cookies. More info

Be first to read the latest tech news, Industry Leader's Insights, and CIO interviews of medium and large enterprises exclusively from Energy Tech Review

Thank you for Subscribing

Digital Oilfields: Future Predictions and Trends

For improving asset performance and value throughout the oil and gas production life cycle, digital oilfields are the way to go.

By

Energy Tech Review | Tuesday, March 07, 2023

Stay ahead of the industry with exclusive feature stories on the top companies, expert insights and the latest news delivered straight to your inbox. Subscribe today.

For improving asset performance and value throughout the oil and gas production life cycle, digital oilfields are the way to go.

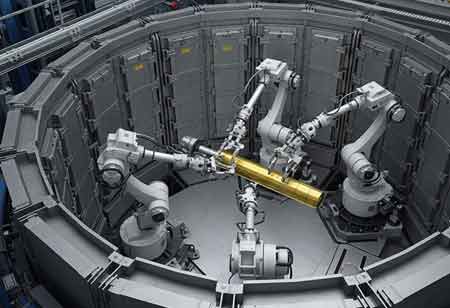

FREMONT, CA: IoT technology and solutions give the oil and gas industry the flexibility, standardization, and innovation required to boost operational and capital efficiencies. Data, like oil, is a very valuable resource that generates enormous growth and profit prospects. The challenge for oil and gas firms is to efficiently gather, analyze, and visualize vast amounts of data from diverse and dispersed sources to provide operational insight and business value while maximizing return on investment. Digital oilfields integrate technology, information, people, and processes to enhance asset performance and value across the life cycle of oil and gas production.

The digital oilfield is a promising technology that can assist operators in optimizing field operations by integrating, interpreting, and acting on production-related data in real-time. To fulfill this potential, organizations must invest in the correct combination of digital technology and equipment to support the asset life cycle's exploration, development, and production phases. The objective of digital or intelligent oilfield solutions is easy to optimize output, enhance operational efficiency, and boost productivity via integrated processes.

Perform more effectively: Real-time controls, distributed analytics, automated workflows, and other technologies can assist businesses in reducing field operations expenses, enhancing asset performance and reliability, and eliminating unscheduled maintenance. Digital oilfields enable oil and gas businesses to utilize predictive analytics, deep learning models, and other data analytics techniques.

Improve safety and health: Digital oilfields enable enterprises to produce in the safest manner possible via remote operations, fewer site visits, and data-driven safety measures. It necessitates devices with built-in, networked intelligence and a network and cloud infrastructure that offers maximum control, flexibility, safety, and visibility.

Improve environmental compliance: Environmental criteria can meet or exceed by oil and gas businesses via more efficient field operations, increased sensor intelligence, and AI-based predictions. Smart digital oilfields differ because all data and procedures linked to asset operations are interconnected.

Collaborate with other teams: Digital oilfields facilitate improved cooperation and communication, resulting in quicker, better-informed decisions by integrating the data across teams and disciplines, from automation engineers to data scientists. At the core of digital oilfield, solutions is a tremendous amount of data that must collect, analyzed, and visualized from sources, including 3-D seismic surveys, well logs, and production and safety systems.

Optimize production: By Utilizing scalable edge computing at their wells and production facilities, businesses obtain improved asset insights that enable optimal operations, production, and recovery. Hundreds of technologies, systems, and measures utilize in every oilfield. It includes fast-loop operations for monitoring equipment and detecting leaks, medium-loop processes for lift optimization, and slow-loop processes for reservoir optimization.

Copyright © 2025 Energy Tech Review. All rights reserved