As the clean energy transition accelerates, solar power is no longer a future bet—it’s the backbone of the new energy economy. In 2024, nearly 90 percent of all new energy capacity came from clean sources—primarily solar, wind, and battery storage. But while solar is booming, one critical challenge remains: most core panel technologies and materials are still produced overseas, with China dominating the global photovoltaic supply chain. One Silicon Valley startup is aiming to shift that dynamic. Tandem PV, a California-based company, is developing a new kind of solar panel that’s not only more powerful but also designed to help restore U.S. leadership in solar manufacturing. At the core of its breakthrough is perovskite, a next-generation crystalline material that, when paired with traditional silicon, captures more sunlight and produces significantly more power than standard panels. “This new technology is a chance to leap ahead because it’s fundamentally different from what conventional silicon offers,” says Tandem PV CEO Scott Wharton. “The U.S. once led the world in solar innovation. We gave that up. It’s time to reclaim that leadership.” More Power , Less Land , Lower Costs Tandem PV’s solution is known as a tandem solar panel, where a thin perovskite layer sits atop a stack of silicon cells. The dual-layer architecture captures a broader range of sunlight, increasing efficiency from the industry standard of around 21 percent to a potential 28–30 percent. That increased performance could reshape the economics of solar energy, especially at scale. Unlike traditional silicon panels—which require massive energy inputs and complex manufacturing—perovskite layers are extremely thin, easier to produce, and highly efficient at capturing light. This technological leap is more than an academic breakthrough. Tandem’s panels pack more energy into every square foot, which is a major advantage for utility-scale solar projects, the company’s primary market. Most of the cost of a solar installation (around 80 percent) isn’t the panels themselves but the land, labor, and infrastructure needed to install and maintain them. By producing more power per panel, Tandem PV’s technology can shrink the size—and the price tag—of solar installations. “Land and labor are expensive,” says Wharton. “With power demand skyrocketing, especially from AI data centers, efficiency isn’t just nice to have—it’s essential.”

Top Oil And Gas Integrated Modelling And Digitalisation Platform 2025

Maximising hydrocarbon recovery in a clean, efficient and economical manner within the upstream oil and gas sector is non-negotiable. It demands a unified, physics-based system built for end-to-end lifecycle integration—where PE (Petex) has set the benchmark. At the core of its offering are the IPM and DOF platforms, enabling operators to model, monitor and optimise performance across the entire production lifecycle. Its 18 world-class modelling tools are designed to interoperate seamlessly, grounded in shared physics, consistent data assumptions and unified architecture. This allows production teams to precisely manage a hydrocarbon molecule’s journey from reservoir to export. That journey begins with geological modelling using MOVE, which incorporates well logs and seismic data to validate and model the subsurface structures which have generated, stored and trapped the hydrocarbons. This end to end system requires fluid flow one end to the other. PVTp used to ensure that the fluid properties are accurately represented at each condition throughout its journey. MBAL then supports material balance calculations for understanding hydrocarbons in place, aquifer drive and depletion, while REVEAL, PE’s full field, fully thermal integrated reservoir simulator, combines traditional reservoir modelling and specialised reservoir studies. When production starts, PROSPER models the wells and GAP/GAP Transient handles the surface network, flow and optimisation. RESOLVE enhances this end-to-end modelling, enabling integration of third-party software into the ecosystem. Once production is underway, the DOF platform connects real-time sensor data with these physics-based models to drive automated visualisation and operational workflows. “The strength of our suite lies in how each tool seamlessly integrates, built on a foundation of consistent data and physics. This results in a system that mirrors the evolving behaviour of the reservoir in real-time,” says Greg Grimshaw, CEO of PE. Adaptability in Action The strength of PE’s IPM and DOF platforms lies in their flexibility to handle the diverse and complex realities of oil and gas operations, from deepwater assets in Brazil to high-pressure gas fields in Southeast Asia and shale plays in North America. The tools are engineered to tackle challenges through geographic customisation and robust configurability that adapts to each reservoir’s unique conditions.

Top Hydrogen & Natural Gas Engine Combustion Solutions Provider for 2025

Every great innovation begins with a question. For Prometheus Applied Technologies, that question was: Can we power the world differently? Founded in 2010 by Luigi Tozzi and Emmanuella Sotiropoulou, the company set out with a clear mission to reimagine internal combustion engines for a more sustainable world. From the start, the vision was bold: cleaner, more efficient engines capable of running on alternative fuels that align with the future of energy. Prometheus began by supplying prechamber spark plugs and combustion solutions for stationary natural gas engines for power generation and gas compression. As its expertise deepened and the demand for cleaner, more efficient systems expanded, so did its reach. Today, the company delivers advanced prechamber technologies, full-scale combustion system development, engineering consulting, and hands-on technical training, partnering with clients to push boundaries rather than accept limits. What distinguishes Prometheus is its integrated approach to combustion. Rather than treating ignition, fuel mixing, and combustion as separate problems, the team views the engine as a unified system. Proprietary computational models and advanced simulation tools allow the company to capture the actual physics of combustion. The result is a suite of solutions that are not only innovative but also grounded in scientific precision. Prometheus works closely with OEMs and Tier 1 providers in sectors ranging from marine propulsion and automotive to racing and UAVs. Each solution is designed to make engines cleaner without compromising performance and validated through rigorous modeling and lab testing. Using alternative fuels like hydrogen, ammonia, methanol, biogas, and natural gas, Prometheus helps manufacturers meet the evolving demands of mobility and power, bridging today’s challenges and tomorrow’s cleaner energy solutions. “At Prometheus, we don’t just adapt engines to cleaner fuels; we reengineer combustion from the inside out, uniting science and strategy to power the future,” says Dr. Luigi Tozzi, Founder and President.

CXO INSIGHTS

Safety Management System

Eric T. Belle , VP Engineering and Standards, and Jonathan DeVries, VP of Strategy and Risk Management, NiSource

The Growing Digital Vulnerabilities of the Power Generation Sector

Julian Kaufmann, Executive Vice President, CAMS

What Role Does Your IT Department Play in SAAS Applications?

Jacque Keenan, Director of Information Technology Business Applications, SRP

Fulfilling Regulatory Compliance with Technology

Brett Adamcik, System Integrity and Reliability Director, CenterPoint Energy

Transforming the Green Tech Industry With Low Carbon Energy

M. Douglas Dagan, Senior Vice President - Renewable Energy, Suburban Propane

IN FOCUS

Perovskite Solar Technology: Revamping Renewable Energy Efficiency

Perovskite solar technology is rapidly advancing at the forefront of renewable energy, generating intense excitement across the photovoltaic landscape.

Harnessing Digital Twins for Safer Nuclear Operations

Digital Twins revamp nuclear maintenance by enabling safe remote operations, enhancing reliability, and shifting from reactive to proactive maintenance through real-time data insights.

EDITORIAL

Balancing Progress in the Energy Transition

What was once experimental has become essential. Clean technologies are no longer background projects tucked away in research labs. They are reshaping how the U.S. lights its cities, fuels its industries, and imagines its economic future. Across the country, several breakthroughs are gaining remarkable momentum, each helping to redefine the nation’s energy story.

Take solar, for instance. For decades, the promise of limitless, affordable power from the sun seemed just out of reach. Now, perovskite cells are changing the equation. Combined with silicon in tandem designs, they produce more electricity at lower cost, unlocking new possibilities for both rooftop panels and sprawling utility farms.

In another corner of the energy world, the oil and gas sector is undergoing its own transformation. Once driven by brute force and heavy infrastructure, operations are now guided by digital ecosystems that tie together subsurface modeling, production forecasting, and asset optimization. AI, cloud computing, and advanced analytics are making it possible to see the entire value chain in real time. Efficiency is rising, emissions are falling, and decisions are sharper. The industry is beginning to balance the realities of hydrocarbon output with the urgency of low-carbon commitments.

Meanwhile, engines that once symbolized emissions are being reimagined as part of the solution. Innovators in the U.S. are advancing hydrogen and natural gas combustion designs that achieve higher thermal efficiency while cutting pollutants. Dual-fuel and hydrogen-ready engines open doors for industries where electrification is not yet practical, offering a bridge from the present to a hydrogen-powered future.

Together, these advances mark a turning point. They signal a shift from incremental improvements to transformative change, moving the U.S. toward an energy future defined by innovation, resilience, and sustainability.

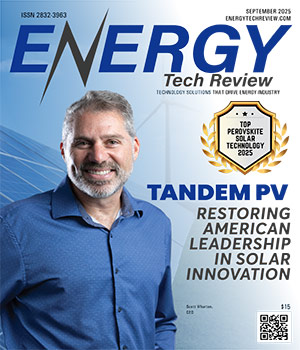

In this edition, we spotlight Tandem PV for its pioneering solar advancements. We also feature insights from Leslie Myers, Product Manager, Renewables at Puget Sound Energy, and Chris Shelton, Senior Vice President | Chief Product Officer | President, AES Next at The AES Corporation [ETR: AES], on the future of clean energy.