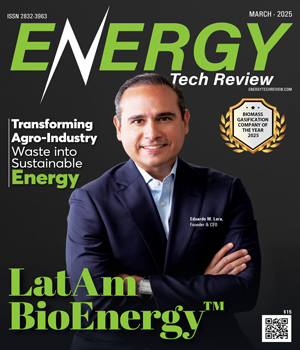

For one of Argentina’s largest olive oil producers, waste management had long been a costly and environmentally damaging challenge. Massive amounts of organic residues— wood from tree pruning and olive pits—were either burned or discarded in ways that harmed the fragile desert ecosystem. That was until Eduardo M. Lora, founder & CEO of LatAm BioEnergy™, stepped in. After assessing the site, he told them, “You have an oil field in your backyard, and you don’t even realize it.” His intervention brought about a visible and impactful change for the Olive producer. LatAm BioEnergy™, a cleantech company, renowned for designing, building, selling, and financing tailored biomass gasification solutions This success story reflects LatAm BioEnergy™’s broader mission: helping agro-industries become more profitable, resilient, and sustainable through cutting-edge clean technology. The Modular BioRefinery: A Smarter Way to Power Agro-Industries At the core of LatAm BioEnergy™’s innovation is the Modular BioRefinery, a 24/7 system that converts agricultural waste— including coconut shells, rice husks, wood chips, and olive and co-generation systems that use AI, helped them create a circular economy. The company converted all their wood chips and olive pits into gas—a valuable resource—rather than burning the biomass or throwing it away. This gas was then used to generate electricity, enabling the olive oil producer to power operations using their own waste, which immediately reduced their energy costs. This success story reflects LatAm BioEnergy™’s broader mission: helping agro-industries become more profitable, resilient, and sustainable through cutting-edge clean technology. The Modular BioRefinery: A Smarter Way to Power Agro-Industries At the core of LatAm BioEnergy™’s innovation is the Modular BioRefinery, a 24/7 system that converts agricultural waste— including coconut shells, rice husks, wood chips, and olive press residues—into clean energy sources such as: Biomass gas – A sustainable alternative to fossil fuels Electricity & heat – For on-site industrial use BioChar – A byproduct that enhances soil fertility and sequesters carbon This regenerative approach not only eliminates waste but also improves agricultural productivity, restoring ecosystems and reducing dependency on fossil fuels. “Our vision is to foster a future where agro-industries are profitable, sustainable, competitive, and less dependent on fossil fuels and its price fluctuation. Our approach to achieving this is to focus on making significant impacts across four key areas: economic, social, environmental, and technological,” says Lora. Another success story comes from the Dominican Republic, where LatAm BioEnergy™’s Modular BioRefinery was deployed at an animal feed production facility, transforming coconut shells and wood chips into electricity, steam, and biochar. This innovative solution not only reduces energy costs and reliance on fossil fuels but also enhances production efficiency and environmental sustainability, setting a new benchmark for clean energy adoption in agro industrial operations. Making a True Impact on the Industry Economically, the company helps clients achieve cost savings and improve efficiency. Socially, it contributes by creating green jobs and promoting sustainable development. Environmentally, LatAm BioEnergy™ drives industry-wide decarbonization. Technologically, it transforms agro industrial operations with clean, renewable energy solutions.

Lithium-Ion Cathode Materials

Manufacturers in the electric vehicle (EV) industry are on a relentless quest for the ultimate battery. They’re seeking high-performance energy storage solutions that offer superior energy density, lightning-fast charging, low costs, unmatched durability, and top-tier safety—demands that extend beyond just power. However, achieving this balance requires significant advances in battery chemistry, engineering, and thermal management systems. Amidst these needs, the industry has been seeking a breakthrough solution to balance safety, cost, and performance— an opportunity Stratus Materials has seized. The company has raised the bar for batteries by developing and producing cobalt-free lithium manganese rich (LMR) cathode active materials (CAMs) that enhance energy storage performance while ensuring safety and thermal stability for optimal battery performance in EVs. Stratus’s brand name for its proprietary CAMs is LXMOTM. Stabilizing Cathode Technology Where many companies in the battery materials space focus on innovations on the anode side of the battery, Stratus Materials’ innovation stands apart because it is on the cathode side. It is one of the only companies to have proven that cobalt-free, LMR materials can be optimized and truly stabilized (as opposed to using coatings or advanced electrolytes, which offer only limited improvements). .

Top Battery Storage

Batteries are the quintessence of our digital age, having rewritten the rules of mobility by freeing us from the confines of stationary power sources. Despite these advancements, limitations in battery life, charging times, and overall energy density raise the question—have we reached the pinnacle of battery technology? Are we doomed to a future of endless searches for power outlets and constant anxiety over dwindling battery levels? Resoundingly, the answer is no. The frontier of battery technology teeters on the edge of another monumental leap, propelled by QuantumScape [NYSE:QS]—a leader in solid-state battery innovation. The endeavor is far from a quest for convenience. With a staggering 300 percent increase in energy density and achieving an 80 percent charge in just 15 minutes, this breakthrough significantly reduces charging times while ensuring devices endure over 1,000 charging cycles with minimal capacity loss. “Lithium-ion batteries served as a crucial step in powering the first generation of electric vehicles (EVs),” explains Jagdeep Singh, co-founder and board chairman of QuantumScape. “We believe our lithium-metal solid-state battery technology paves the way for the next generation of batteries, establishing a foundation for a transition to a more fully electrified automotive fleet.” QuantumScape’s innovation signals a transformative shift towards more sustainable and efficient energy solutions, heralding a new era in technology and transportation. The Key to High-Performance Lithium Metal Battery The core of QuantumScape’s technology lies in a solid-state ceramic separator, which significantly departs from the traditional polymer separators used in lithium-ion batteries. This cutting-edge separator, crafted from ceramic material, is the cornerstone of the battery’s enhanced performance. It features several key advantages—unparalleled conductivity for swift ion flow, remarkable stability against lithium metal to endure high voltages and currents, robust resistance to dendrite formation to avert short circuits and minimal interfacial impedance to curtail resistance and heat generation. These features are instrumental in harnessing the potential of a lithium metal anode, pivotal for achieving higher energy density, expedited charging and prolonged battery life. [CIOS_QUOTES_REPLACE]QuantumScape’s battery design innovatively eliminates the need for an anode in its initial state, opting for an anodefree configuration manufactured in a discharged state. This unique design approach allows the battery to form its anode of pure metallic lithium during the first charge cycle, as lithium ions traverse from the cathode through the atomic lattice of the solid-state ceramic separator and deposit between the separator and the electrical contact. The process minimizes the use of lithium to what is strictly necessary, eliminating waste and reducing costs, pointing out its commitment to efficiency and environmental sustainability. The advantages of employing a solid electrolyte over a liquid one are manifold, particularly in terms of safety and durability. QuantumScape’s solid-state lithium metal battery significantly mitigates the risks associated with traditional batteries, offering a safer alternative that matches real-world applications’ thermal and mechanical stresses. In the event of a car accident, for instance, the ceramic separator provides a thermally stable barrier between the anode and cathode, greatly enhancing the battery’s safety profile. A New Era in Cell Architecture Traditional battery designs often struggle to accommodate the physical changes during charging and discharging cycles, limiting their efficiency and longevity. Addressing this challenge, the FlexFrame cell format represents a culmination of ingenuity in battery technology. It marries the benefits of the pouch and prismatic cell formats, fostering a significant leap forward by accommodating the natural physical changes a battery undergoes during charge and discharge cycles. The essence of the FlexFrame architecture lies in its unique design. A frame encases the edge of the cell stack, complemented by a flexible outer layer made from a polymer laminate akin to materials used in conventional pouch cells. This innovative combination ensures the cell’s face rests discreetly millimeters below the surrounding frame when the battery is at rest or most contracted.

CXO INSIGHTS

Permitting Challenges for Solar and Battery Storage Projects in Colorado

Jonathan Berry, M.S., Utility Scale Development Manager, RWE [XETR: RWE]

Leading The Charge In The Energy Revolution

Matthew C. Coates, VP Development, NextEra Energy

Powering The Future Of Electric Mobility

Cuong Nguyen, Senior Manager Of Cell Engineering, Rivian

Combining Technical Expertise With Strategic Vision For Effective Cio Leadership

Sheila Mendez, Vice President and Chief Information Officer, TXNM Energy, Inc

Embracing The Cloud: Summit Utilities' Transition To Azure

Cannon Lord, Manager of Data and Analytics, Summit Utilities

IN FOCUS

Driving Change: The Evolution of Lithium-Ion Cathodes for a Sustainable Future

The lithium-ion battery sector, a critical facilitator of the shift to renewable energy and electric vehicles (EVs), has made remarkable advances, notably in cathode materials.

Biomass Gasification: A Sustainable Pathway to Clean Energy

Biomass gasification is gaining global attention as a sustainable energy solution that converts organic materials into syngas (synthetic gas) for power generation, industrial applications, and biofuel production.

EDITORIAL

A Greener Future Driven by Technological Advancements

Clean energy uptake has skyrocketed in recent years. Thanks to the dipping prices and wide availability of technology, investment in new clean power now outpaces investment in fossil fuels— progress that will help the world solve the energy transition puzzle.

In this edition of Energy Tech Review, we delve into the recent developments in the energy tech sector and explore how companies are harnessing cutting-edge technologies to stay abreast of challenges and establish a strong presence among the public.

Biomass gasification is gaining momentum as industries seek sustainable energy solutions. The technology, which converts organic materials into syngas for power generation and biofuel production, is rapidly evolving due to advancements in efficiency, feedstock flexibility and carbon capture integration. Innovations in gasifier design, like dual fluidized bed and plasma gasification systems, improve conversion rates while reducing tar formation and contaminants. Powered by such developments, the biomass gasification market industry is projected to grow from USD 112.51 Billion in 2024 to USD 199.2 billion by 2032, registering a CAGR of 7.40 percent during the forecast period.

The edition will also examine the latest trends in lithium-ion cathode materials and bring leaders who can deliver adept solutions to the forefront.

The growing adoption of electric vehicles (EV) in the quest for a greener tomorrow has sparked the need for efficient energy storage solutions. In EVs, lithium-ion batteries are the driving force behind the shift from fossil fuels to clean energy. They provide the high energy capacity needed to deliver long driving ranges, rapid acceleration and fast charging times–all critical factors in making EVs a viable alternative to traditional combustion-engine vehicles.

We feature insights from industry expert Amy Carstens, Director, Corporate Strategy, Planning & Analysis at Dairyland Power Cooperative. She sheds light on how renewable generation has dramatically changed the way transmission systems function and how utilities must plan to preserve service reliability. Ensuring a safe work environment isn’t merely about compliance; it’s about fostering an inclusive safety culture that values and protects everyone, irrespective of their background.