Well control in oil and gas drilling has been progressing, though at a relatively sluggish pace. Operators rely on manual systems, reactive decisions and conventional methods. SafeKick is rewriting the status quo. Over the last 15 years, SafeKick, led by President Helio Santos, has been quietly transforming well control practices through smarter software and advanced equipment. By developing a fully integrated system that combines an automated choke for well control manifolds with simulation and monitoring software that models well conditions in real time, the company equips drilling crews with the tools to handle well control more accurately, quickly and safely. This blend of advanced technology and operational insight marks a significant shift in how well control is executed on today’s rigs. “SafeKick doesn’t just automate the process; we created a system where equipment and software work in tandem to empower crews to handle well control more precisely and efficiently,” says Santos. SafeKick’s initial breakthrough was the development of an automated choke engineered to integrate with the well control manifold used during kick events. Until 2015, these chokes were mostly manually operated or with limited automated pressure control, without any smart component added to it, making them prone to human error and delays in critical situations.

Sustainable Energy Solution

Batteries are the quintessence of our digital age, having rewritten the rules of mobility by freeing us from the confines of stationary power sources. Despite these advancements, limitations in battery life, charging times, and overall energy density raise the question—have we reached the pinnacle of battery technology? Are we doomed to a future of endless searches for power outlets and constant anxiety over dwindling battery levels? Resoundingly, the answer is no. The frontier of battery technology teeters on the edge of another monumental leap, propelled by QuantumScape [NYSE:QS]—a leader in solid-state battery innovation. The endeavor is far from a quest for convenience. With a staggering 300 percent increase in energy density and achieving an 80 percent charge in just 15 minutes, this breakthrough significantly reduces charging times while ensuring devices endure over 1,000 charging cycles with minimal capacity loss. “Lithium-ion batteries served as a crucial step in powering the first generation of electric vehicles (EVs),” explains Jagdeep Singh, co-founder and board chairman of QuantumScape. “We believe our lithium-metal solid-state battery technology paves the way for the next generation of batteries, establishing a foundation for a transition to a more fully electrified automotive fleet.” QuantumScape’s innovation signals a transformative shift towards more sustainable and efficient energy solutions, heralding a new era in technology and transportation. The Key to High-Performance Lithium Metal Battery The core of QuantumScape’s technology lies in a solid-state ceramic separator, which significantly departs from the traditional polymer separators used in lithium-ion batteries. This cutting-edge separator, crafted from ceramic material, is the cornerstone of the battery’s enhanced performance. It features several key advantages—unparalleled conductivity for swift ion flow, remarkable stability against lithium metal to endure high voltages and currents, robust resistance to dendrite formation to avert short circuits and minimal interfacial impedance to curtail resistance and heat generation. These features are instrumental in harnessing the potential of a lithium metal anode, pivotal for achieving higher energy density, expedited charging and prolonged battery life. [CIOS_QUOTES_REPLACE]QuantumScape’s battery design innovatively eliminates the need for an anode in its initial state, opting for an anodefree configuration manufactured in a discharged state. This unique design approach allows the battery to form its anode of pure metallic lithium during the first charge cycle, as lithium ions traverse from the cathode through the atomic lattice of the solid-state ceramic separator and deposit between the separator and the electrical contact. The process minimizes the use of lithium to what is strictly necessary, eliminating waste and reducing costs, pointing out its commitment to efficiency and environmental sustainability. The advantages of employing a solid electrolyte over a liquid one are manifold, particularly in terms of safety and durability. QuantumScape’s solid-state lithium metal battery significantly mitigates the risks associated with traditional batteries, offering a safer alternative that matches real-world applications’ thermal and mechanical stresses. In the event of a car accident, for instance, the ceramic separator provides a thermally stable barrier between the anode and cathode, greatly enhancing the battery’s safety profile. A New Era in Cell Architecture Traditional battery designs often struggle to accommodate the physical changes during charging and discharging cycles, limiting their efficiency and longevity. Addressing this challenge, the FlexFrame cell format represents a culmination of ingenuity in battery technology. It marries the benefits of the pouch and prismatic cell formats, fostering a significant leap forward by accommodating the natural physical changes a battery undergoes during charge and discharge cycles. The essence of the FlexFrame architecture lies in its unique design. A frame encases the edge of the cell stack, complemented by a flexible outer layer made from a polymer laminate akin to materials used in conventional pouch cells. This innovative combination ensures the cell’s face rests discreetly millimeters below the surrounding frame when the battery is at rest or most contracted.

Energy Intelligence Platform

GridPoint is a leading energy efficiency solutions company that provides a unified software platform to analyze electrical appliance data in commercial buildings. By identifying inefficiencies and optimizing energy management, the company helps businesses reduce consumption, lower utility costs, and enhance sustainability. The platform leverages predictive analytics and intelligent automation to create a seamless energy monitoring system, delivering real-time diagnostics and robust energy data. Beyond energy monitoring, GridPoint recognizes the critical role of asset management in energy optimization. Its advanced tools track and maintain essential business assets, such as HVAC systems and refrigeration units, ensuring peak performance. Features like automated anomaly detection and HVAC health monitoring help businesses prevent costly breakdowns, extend equipment lifespan, and improve overall efficiency. With real-time asset intelligence, companies gain valuable insights into equipment performance, energy usage, and maintenance needs. Effectively managing energy demand is crucial for businesses aiming to control costs and prevent excessive utility charges. GridPoint helps companies optimize their energy consumption in response to peak pricing, aligning usage with operational needs and mitigating demand surges that lead to higher costs. Adapting to extreme weather conditions, companies can reduce unexpected financial burdens and maintain operational efficiency through intelligent demand management strategies.

Top Nuclear Remote Handling Containment Solution 2025

In the high-stakes worlds of nuclear and pharmaceutical industries, progress never hits pause. Scientific breakthroughs, evolving regulations and the constant pursuit of efficiency are on a relentless march. The path forward depends on technologies that can evolve alongside the industries they serve, ensuring precise, secure and contamination-free solutions in increasingly demanding conditions. For more than 80 years, Central Research Laboratories (CRL) has been at the forefront of developing precision containment and remote handling solutions. From telemanipulators to transfer systems and glove ports, CRL engineers and manufactures technologies that enhance safety and efficiency for operators in the nuclear and life sciences industries. While the use cases are complex, these tools solve a very basic human problem: performing hands-on work in places that are unsafe or must remain untouched. Telemanipulators, for instance, are long-arm tools that mimic human hand movements through thick radiation-shielding walls. Unlike robots, every movement of the device is directly controlled by a human operator from a safe distance. CRL’s first public demonstration of a telemanipulator took place in 1949, marking the start of a product line that has truly stood the test of time. “Some of our equipment has been in service for nearly 70 years, which speaks to its quality. Many customers, especially in government nuclear facilities, still rely on us to support and maintain machines we’ve built decades ago,” says Rob Weber, manager of projects and proposals. CRL’s strength lies in combining tried-and-tested engineering with the ability to customize everything it builds to exact client requirements. Whether it’s adjusting for a new environment, increasing load capacity or keeping things sterile, the company doesn’t offer off-the-shelf solutions. It builds what works for that specific challenge. This adaptability has been central to CRL’s long-term success. Initially focused on nuclear containment, the company expanded in the 1970s to isolator and glove box technologies, evolving to support critical environments in labs, government facilities and pharmaceutical manufacturing.

CXO INSIGHTS

The Key To Reducing Fuel Consumption And Reduced Environmental Footprint

Frode Jensen, President Rig Technologies, National Oilwell Varco [NYSE: NOV]

The Offshore Green Energy Chain

Adnane Bennani, Battery Storage Service Bid and Project Manager, Siemens Energy

Navigating the Tides of Change in the Natural Gas Industry

Mark Reese, Vice President, U.S. Natural Gas Supply, Just Energy

Identifying the Value in Automating the Drill Floor

Jeremy Angelle, VP of Well Construction, Expro [NYSE: XPRO]

Risk Management in the Face of Legal Challenges

Alvaro Valdez, Assistant Management Services Director - Risk Management & Safety, City of Burbank

Advent of AI in Public Safety

Tina Rodgers, Director Safety and Risk Management, San Manuel Band of Mission Indians

Compensated Fuels: Enabling Energy Transition W/O Breaking The Bank

Jonathan (J.W.) Hackett, Senior Director, Environmental Products, Global Partners LP

IN FOCUS

Reinventing Nuclear Containment and Remote Handling for the Next Era

The nuclear energy sector is evolving with advanced remote handling and containment technologies to enhance safety and efficiency while managing radioactive materials responsibly.

EDITORIAL

The Next Frontier in Remote Handling Containment Technology

With the global shift toward low-emission energy systems underway, nuclear power continues to serve as a dependable source of clean energy. At the same time, the demands on operational safety, containment reliability and maintenance precision are growing more intense than ever. In this high-stakes environment, remote handling containment solutions have emerged as critical enablers—safeguarding human operators while delivering the agility needed to perform complex tasks in some of the most hazardous and highly regulated settings.

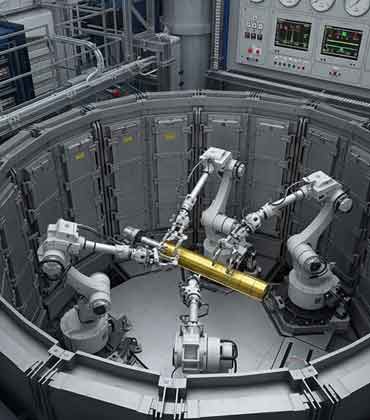

Today’s containment systems are far more than passive safety barriers. Enabled by robotics, precision engineering and digital control interfaces, they serve as active extensions of human expertise—executing delicate procedures, managing radioactive materials and ensuring critical systems remain accessible without exposure risk.

What distinguishes leading solutions in this space is their fusion of structural integrity with intelligent design. From modular containment chambers to robotic arms capable of fine manipulation in zero-access zones, these platforms combine mechanical resilience with advanced remote operability. Their architecture is engineered to adapt, supporting everything from new reactor builds and legacy upgrades to decommissioning efforts and emergency interventions.

Usability stands as a key pillar alongside technical strength. The most effective systems prioritize operator experience with ergonomic controls, realtime visual feedback and automation-assisted precision, enabling smoother operations and fewer risks under pressure. When the margin for error is razorthin, intuitive systems become necessities rather than conveniences.

Adaptability is also a core feature. As global regulatory frameworks evolve and infrastructure ages, nuclear facilities require solutions that are as flexible as they are robust. Scalable, future-proof systems that integrate easily into broader safety and operational protocols are fast becoming the benchmark.

In this edition, we examine how innovations in remote containment and handling systems are redefining operational effectiveness in the nuclear industry. The magazine highlights top solution providers that are paving the way for safer, more efficient and future-ready nuclear operations.

We also present insights from expert CXOs like Julian Kaufmann, Executive Vice President, CAMS and Jason M. Biggers, Director of Technology, Hillsborough County, who offer their perspectives on today’s best practices and tomorrow’s priorities. We hope the expertise and solutions featured here provide meaningful direction as you plan your next move in this critical space.

Let us know your thoughts!