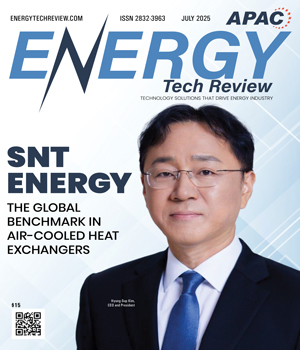

SNT Energy is the world’s largest manufacturer of air-cooled heat exchangers, accounting for more than 40 percent of global output. Its manufacturing hubs in Changwon and Gunsan (South Korea) and Dammam (Saudi Arabia), which sell 7,200 units annually, have positioned SNT not just as a supplier but as a cornerstone of energy reliability. A defect rate below 0.5 percent reflects the level of manufacturing precision built into every SNT heat exchanger. Each unit is built with corrosion-resistant alloys tailored to its environment—whether stainless steel, duplex, clad steel, copper-nickel or titanium. The result is lasting durability and reliable performance, even in the harshest field conditions. Wherever high-performance cooling is critical—whether in the deserts of the Middle East, LNG terminals along the U.S. Gulf Coast, industrial builds in Southeast Asia, refineries across Western Europe or coastal power plants in Latin America—SNT Energy delivers with scale, speed and assurance. An on-time delivery rate above 95 percent keeps complex projects moving, while a client satisfaction score of over 99 percent speaks to the consistency, quality and trust built into every unit shipped. “We became the world’s largest by delivering when it counted, staying consistent and proving we’re built for certainty in high-stakes environments,” says Hwa-Su Yu, sales team leader. “We’re focused on securing long-term agreements, leading technically through disciplined execution and making sure that even under the toughest conditions, we never compromise on quality or reliability.” It’s this mindset that has earned SNT the trust of some of the most respected names in energy. In Saudi Arabia, SNT holds a Corporate Procurement Agreement with Aramco, allowing its EPC partners to source directly from SNT under pre-approved terms. This early-stage alignment simplifies procurement, reduces risk and ensures seamless integration from day one. The same operational discipline played out across the Atlantic. During the Rio Grande LNG project in the U.S., led by Bechtel, SNT delivered months ahead of schedule, without shortcuts or last-minute fixes. It was the result of detailed coordination, resilient production systems and a culture built around delivering exactly when it matters most. Behind every SNT unit is a design process built for performance in the real world. Precision isn’t added later. It’s embedded from the start through a specialized software stack that guides each phase of engineering. Thermal efficiency is validated using industry-recognized platforms like HTRI, structural strength is modeled through Bentley’s STAAD Pro and pressure-part calculations are performed with proprietary in-house tools tailored to ACHE systems. AutoCAD and Inventor support detailed layout, modeling and part integration, ensuring each unit fits complex site requirements with minimal adjustment.

Energy Storage Solution

The future of global energy is clear: clean and decentralized power is the way forward. As governments push for cleaner power solutions, companies with the right attitude regarding renewable energy generation and storage stand poised to reap the benefits. Japan, in particular, is taking steps to expand its energy infrastructure and reduce CO2 emissions by 2030, aiming to move closer to a fully renewable energy economy. Re:Power Inc., the country’s first energy storage solutions provider is fully equipped and ready to aid the government’s initiatives through innovative solutions that address both scalability and sustainability. Dr. Shoji Fuchigami, a seasoned executive with experience at SONY, leads the company as CEO, supported by former industry giants such as TDK and NEC as outside directors and advisors, lending it credibility in technology and energy management. Grounded in advanced technology and backed by the government, the company is simultaneously responding to Japan's increasing energy needs while continuing to make waves on the international stage. “Our core technologies are engineered to transform energy resilience and reliability, empowering both domestic and global markets to transition toward a sustainable, decentralized energy future,” says Dr. Shoji Fuchigami, president and CEO of Re:Power Inc. A Comprehensive Energy Storage System The company has devised an energy ecosystem comprising storage devices, energy management systems (EMS) and AI-enabled energy trading systems. This multilayered structure is similar to internet providers, connecting devices to the web through the operating system and network. Its offerings are focused on managing this entire system to ensure maximum efficiency and profitability. The centerpiece of Re:Power’s system is its energy storage solution, the Re:Power Cube. This cutting-edge water-cooled storage battery system is characterized by exceptional scalability, providing both capacity and functionality adjustments. The cube's versatility allows it to be used for various applications, from commercial facilities to large-scale grid-connected systems. The system is also compatible with advanced technologies like lithium-ion, sodium-ion and redox flow batteries and can accommodate future technological evolutions.

Sustainable Hydrogen Fuel Cell Solution

What if the most abundant element in the universe powered industries, homes and transportation— all while leaving nothing behind but water? YC Synergy’s hydrogen fuel cells are turning this vision into reality by supporting RE100 initiative and driving zero-emission technology for a cleaner, sustainable future. Over 15 years at the forefront of clean energy innovation have enabled YC Synergy not just to develop a solution but lead a transformation. Its cutting-edge hydrogen fuel technology opens new doors for versatile energy solutions that can be adapted to various applications. What makes YC Synergy’s technology so different? While other fuel cell technologies, such as solid oxide fuel cells (SOFC) and phosphoric acid fuel cells (PAFC), have made strides, they often rely on natural gas, preventing a full transition to sustainable energy. YC Synergy takes a different approach with low-temperature Proton Exchange Membrane (PEM) fuel cells. These systems offer a rare level of flexibility in the industry—the option to switch them on and off to integrate with renewables like solar and wind, creating a truly flexible energy system. Its technology taps into hydrogen’s potential through electrochemical reactions, where hydrogen and oxygen meet. This recombination powers devices and transforms energy systems, producing clean electricity with only water and heat as byproducts. It is clean, efficient and ready to reshape industries with renewable energy integration. Take a manufacturing facility for example. During peak sunlight hours, the factory relies on solar power. But when demand spikes and electricity becomes more expensive, YC Synergy’s hydrogen fuel cells kick in, providing stable, cost-effective energy, reducing emissions and enhancing overall grid stability. This empowers the facility to achieve net-zero emissions without compromising their operational needs. “Our mission is simple; we make things happen,” says Mark Huang, CEO. “Hydrogen isn’t here to replace solar or wind— it’s here to complement them. When the sun isn’t shining and the wind isn’t blowing, our technology becomes a reliable, sustainable solution to meet the world’s energy needs.” Charting New Waters with Green Marine Technology YC Synergy is working alongside Porrima, Taiwan’s largest green energy startup, on an ambitious project to transition from diesel-powered boats to hydrogen-fuel cell-driven vessels. This collaboration marks a significant step toward cleaner marine transport. Supported by Taiwan’s government, Porrima has already introduced solar-hydrogen-powered ferries for small and medium-sized water routes, particularly benefiting island nations that rely heavily on these forms of transport. YC Synergy’s contributions to the project have been nothing short of phenomenal. YC Synergy act as the system architect and integrator simultaneously of hydrogen system in Porrimas vessel, including each hydrogen relevant systems such as power output integrating PEM fuel cells into the tight quarters of the vessels, hydrogen production via electrolyzers on ship, hydrogen carbon fiber storage and onshore hydrogen refueling station. This success builds on YC Synergy’s impressive track record in offshore transportation. In addition to maritime application, YC Synergy also has successfully launched hydrogen buses, cold-chain trucks and heavy-duty trucks operated from 2018 till now. What truly made this project shine is YC Synergy’s comprehensive approach to hydrogen energy. Instead of just focusing on one aspect, it thoughtfully covers every stage of the hydrogen cycle—from production and storage to practical application. By expertly blending solar energy, creating green hydrogen, and optimizing fuel cells, YC Synergy offers a flexible and personalized solution that truly distinguishes it from many of its peers in the field. Driving Innovation through Practical R&D “We don’t innovate just to say we’ve done it. We start with a problem that needs a solution, then work to find the right answer,” says Huang. YC Synergy’s R&D team is focused on solving real-world challenges and is driven by hands-on experimentation.

CXO INSIGHTS

Repurposing Resources: Installing New Battery Energy Storage Utilizing Existing Infrastructure

Julian Kaufmann, Executive Vice President, CAMS

Safety Management System

Eric T. Belle , VP Engineering and Standards, and Jonathan DeVries, VP of Strategy and Risk Management, NiSource

Production of Biogas and Biodiesel From Organic and Commercial Byproducts

Marjun Manahan, Operations Technology Head, Manila Water

Why adopt Operational Readiness for your projects?

Greg Roberts, Asset Management Lead, Verbrec Ltd [ASX: VBC]

Grid Transformation Engine

Ben Bristow, Head of Grid Transformation, Western Power

The Broader View of Sustainability!

Dominic Dowling, Global Head of Sustainability & Risk, EDL

Watercare's Journey Towards Sustainability: Harnessing Solar Energy

Damien Dupont, Project Manager - Renewable Energy Strategy & Planning, Watercare Services Limited

Unlocking Australia's Energy Future

Jess Padman, Director of Energy Products, NRN

Fulfilling Regulatory Compliance with Technology

Brett Adamcik, System Integrity and Reliability Director, CenterPoint Energy

IN FOCUS

The Adoption of Dry Cooling in APAC's Power Sector

APAC's power sector is transitioning to dry cooling technologies due to stringent water regulations, advancing sustainability efforts amid rising water scarcity and environmental pressures.

ACHE Innovation at the Heart of APAC's Sustainable Expansion

The APAC air-cooled heat exchanger market is experiencing rapid expansion, driven by industrialization, sustainability, and technological advancements, which highlights a growing demand for efficient cooling solutions.

EDITORIAL

Smart Cooling Systems Shaping APAC Tomorrow

Air-cooled heat exchangers have stepped out of the shadows. Once simple cooling systems, they now stand at the heart of sustainable infrastructure across Asia Pacific. As industries expand and environmental demands intensify, these systems reshape how plants operate and how energy networks come to life.

The new generation blends engineering with intelligence. Digital diagnostics and IoT monitoring have moved from novelty to necessity. Operators no longer wait for mechanical issues to escalate. Early detection and real-time data optimize heat transfer and cut energy use, creating leaner and smarter operations.

Design has evolved, too. Modular frameworks and refined fin-tube geometries make exchangers more adaptable. Whether in petrochemical plants, power stations, data centers, or renewable facilities, they bring flexibility aligned with today’s fast-changing industrial landscape.

These innovations meet rising expectations around ESG commitments and operational safety. Air-cooled systems conserve resources while maintaining efficiency in a region where water scarcity meets soaring energy demand. They avoid the environmental costs of water-based cooling, offering plants a reliable path to sustainability.

The market reflects this momentum. Asia Pacific’s air-cooled heat exchanger market is projected to reach $2.08 billion by 2030, growing at 7.3 percent a year. Forced-draft exchangers continue to lead with compact designs and broad utility. Induced-draft systems are gaining recognition for superior performance in high-temperature conditions.

Together, these trends signal a future where thermal management is no longer an afterthought. It is adaptive, energy-efficient and central to Asia Pacific’s next generation of resilient infrastructure.

The magazine features thought leadership articles from Todd Hranicka, Director - Energy Services at Public Service Electric & Gas Company [NYSE: PEG], who draws attention to the role of storage and distributed systems in reshaping grid operations. His perspective on long-term energy resiliency and equipment integration echoes the region’s growing push toward multipurpose infrastructure and thermal-electric synergies.

We feature insights from Min Yang, Head of Onshore AP EN at Siemens Gamesa, highlighting the need for adapted turbines, strong foundations, and real-time monitoring to ensure nearshore wind farms operate efficiently in challenging marine conditions.

We hope you find the right partner to meet your organization’s cooling and infrastructure goals.